It was Snowing today saw Nopheads new Heated Bed.. excellent Idea had to Make one.

As I knew I had almost all the bits even though they are all scrap.

Aluminium sheet from an DIY Radio I built in 1970. Magnets left over from Bathroom re-fit used 40 20mm neodym magnets to hold 300mm x 300mm wall tile / covers all the plumbing shut off taps. Tile is removed to access taps with a 4" glass sucker some puling.

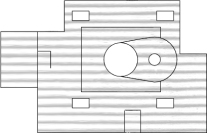

Thin steel plate for printing on an old Mitsumi 3.5" disc drive cover. So heated bed is cut to 130mm x 99mm inside dimensions of a disk drive.

Cut the 3.3mm thick Aluminum plate to inside dimensions of a disk drive.

So heated bed will be 130mm x 99mm x 3.3mm.

Stand off material had choice of Perspex ABS chopping board and MDF.

Decided MDF easiest least likely to be upset by temprature.

Blind 2mm deep 22mm holes for magnets found 2 2 ohm AL clad resistors checked with Nophead if he thought they were big enough. Marked out position drilled 2 big holes so the can mount through MDF.

Drilled and tapped aluminum for power resistors to fit. Screwed it all together added two 12mm thick strips of MDF as stand offs to mount heated bed to Mendel printing Bed.

Have left two holes in plate for Thermocouples one will be fitted the other is for calibration.

I will use the second extruder controller as a PID control for the heated bed.

Still waiting for 4 Meccano worm gears to arrive so cant test my extruders yet.

I will be setting up extruder controllers next flashing the boot then trying out the Software for temprature control on both extruder and Bed.

Thanks to Nopheads latest post I will have a heated bed without spending a penny.